FIFO (First In, First Out) Lot Coding System

Lot codes for Raw Materials and Finished Goods are now tracked over time, from manual updates to production runs! This means you'll know how much of each lot code is available, in addition to the overall inventory levels.

The Overview

You've been able to enter your lot codes for manual inventory updates and production runs, and those lot codes are connected to all of your updates for the purpose of lot tracing and recalls. But the system wasn't keeping track of lot code amounts. We didn't have a formal way to track in the database how much of each lot code there was in inventory and when it was first added or last used.

Now we do track all of that and update it when you create a new lot code (e.g. when adding to raw materials), use one in production, or subtract it from inventory so that the system can tell you which lot is up next (using FIFO) for an inventory item and how much is left.

The Details

- Whenever you include a lot code in a manual inventory update or a production run, its amount and date added/used will get updated.

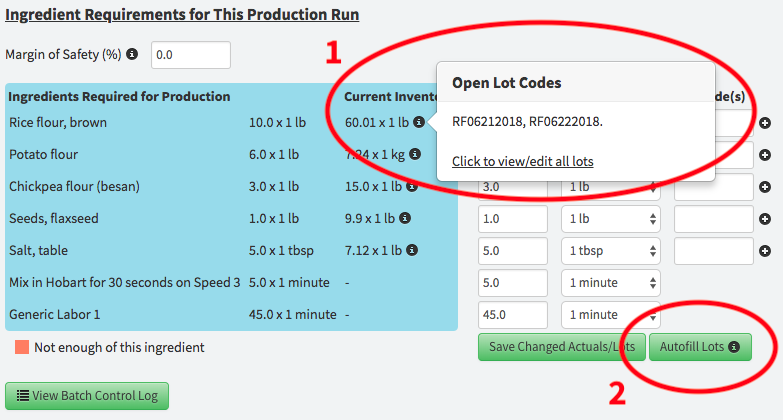

- You can view "open" lots in the info popup on your inventory pages and production runs (see section 1 highlighted in the image below):

- You can edit amounts and set whether a code is indeed still available or not on the lot code page. You'll find links to that page in the info popup (in the image above) and on the history page for that inventory item.

- The most recently used open lot code or the most recently "added to inventory" open lot code will be the first to be used in the FIFO system, as long as the code is set as being available.

- In your production runs you can automatically fill in lot codes based on the amount of each ingredient in the production run just by clicking the Autofill Lots button (see section 2 highlight in the image above).

- And when you close the production run, the amount of the raw materials lots and finished good lot will be updated as well as the current inventory amounts for raw materials and finished goods so that everything is up to date.

- The autocomplete feature for lot codes will now only show open lot codes (where appropriate), making it more accurate, faster, and easier to work with.

We heard your comments that this type of automation would be a good feature, and we hope it makes the inventory module more useful. Let us know what you think and reach out with any questions!