Common Recipe Yield Issues (and how to fix them)

A question we sometimes get from users is how to fix a recipe yield that seems off. ReciPal compares the weight of a recipe’s inputs to the weight of its output to determine a recipe’s yield. The yield percentage is a sense check that helps highlight if your output is outside the typical range. While there isn’t any right or wrong answer in terms of what your yield percentage should be, extremes often indicate something in your recipe is off.

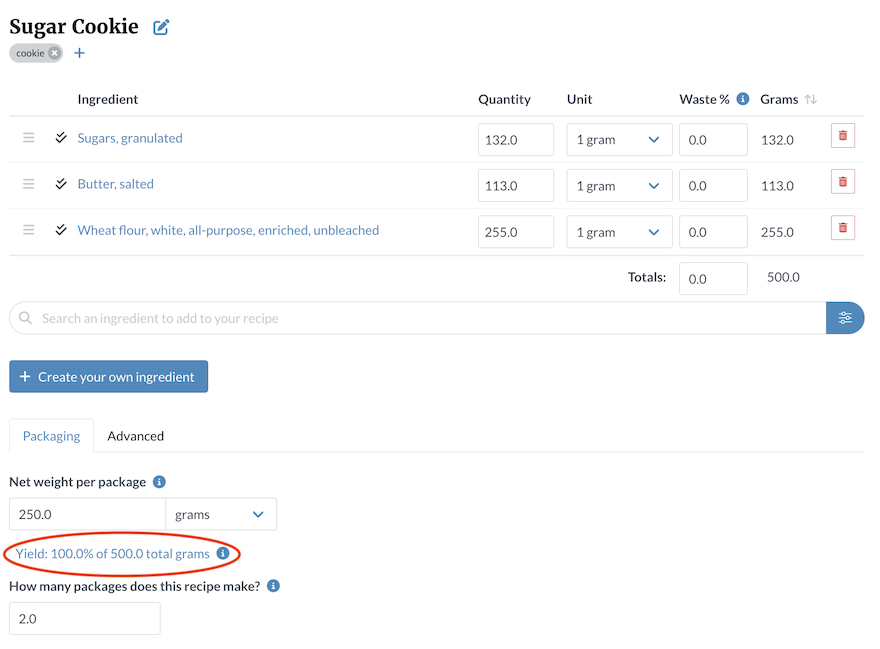

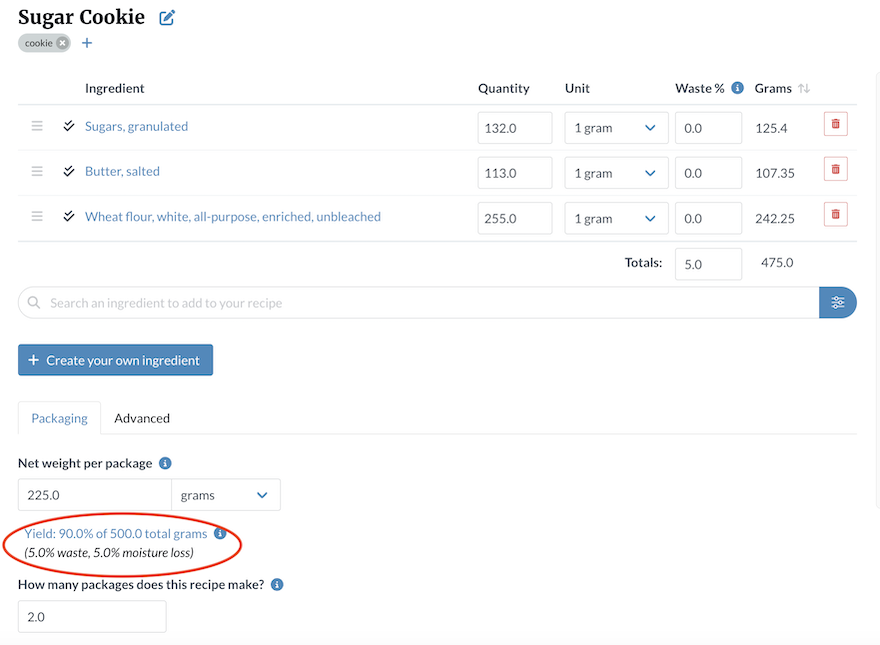

Let’s work through an example yield calculation. Let’s say the total weight of ingredients for a cookie recipe is 500 grams. This recipe produces 2 packages that weigh 250 grams each. In this case the yield is 100% because the weight of the inputs (500 grams) is equal to the weight of the output (2 packages x 250 grams/package).

Yields Lower Than 100%

In many cases, it is expected that the yield will be somewhat below 100%. Two reasons for this are waste and moisture loss.

Waste is any amount of ingredients that do not end up in the final product. For example, in this cookie recipe, a small amount of the cookie dough may be left behind in the mixing bowl. In ReciPal you can set the waste at an individual ingredient level or for the recipe as a whole. In this case, let's say 5% of the cookie dough gets left behind. When we set the waste, it will remove that percentage of ingredients from the nutrition calculation.

Moisture loss is the other factor that accounts for yields of less than 100%. In this case, cooking processes cause water to evaporate and the end product to weigh less as a result. You can easily figure out the moisture loss by weighing your product before and after cooking it. In ReciPal, you set your moisture loss by adjusting the net weight per package to the appropriate amount. When we lower the net weight per package the same amount of nutrients remain, but are more concentrated. In our example, the pre-baked cookies weigh 475 grams (500 grams - 25 grams of waste). After baking our cookies, we find that the total weight of the cookies is 450 grams. With two packages that comes out to a net weight of 225 grams/package.

Here the system will let you know that your yield is 90% with 5% waste and 5% moisture loss. Again, this is a completely reasonable yield. If your yield is below 70% or above 100% ReciPal will highlight it in red. If you fall into this category it doesn’t necessarily mean something is wrong, just that you should double check to make sure everything looks right. If you end up with a yield that is lower than your expectations here are some things you can check.

What to do if your yield is too low?

- Check for duplicate ingredients - ReciPal provides a warning if you add the same ingredient to a recipe more than once. However, sometimes users update an ingredient with a variation and forget to remove the old version.

- Choose the most accurate units - Depending on the ingredient, you may have a number of different units to choose from. In cases of volume measurements, selecting the right form of the ingredient will have an impact on its weight. For example, a cup of powdered sugar could be sifted (95 grams) or unsifted (114 grams).

- Weigh everything - When all else fails, check the scales. Confirm the weight of your ingredients and end product. Are you accurately accounting for waste? Is there any volume measurement where the weight is off? If the scale confirms your results then you may just have a product with a particularly low yield.

Yields Higher Than 100%

A yield over 100% is a bit of a head scratcher. While yields are expected to be under 100%, it’s hard to get over 100% without breaking one or more laws of physics. Ice creams can be the exception to this rule.

Keep in mind that the net quantity of the contents must be shown by a fluid measure for food that is liquid or in terms of weight if the food is solid, semisolid, or viscous, or a mixture of solid and liquid. The FDA regulation goes on to say that “in the case of frozen food that is sold and consumed in a frozen state, express the volume at the frozen temperature.” So our ice cream fans will certainly know that ice cream is sold by the pint (a volume measure) and the reference amount for a serving size is ⅔ cup (though many times it feels like it should be more than that).

In the case of ice cream, the volume of the end product can be greater than the volume of the ingredients because air is added as it’s churning. This air acts as an invisible ingredient that increases the volume. The amount the volume increases through the addition of air is called the “overrun”. In some instances the overrun can cause the volume of the end product to be more than double that of the ingredients.

Here’s where the confusion can enter. Some people assume that because their package is one pint (a volume measure) that their net weight per package is 16 ounces (a weight measure). However, two food products of the same volume can have vastly different weights. Remember, weight and volume do not necessarily operate on the same scale. A pint of ice cream with lots of air will weigh less than a dense pint of ice cream, even though they’re both one pint.

So unless you fall into a category like ice cream where 1) the product uses a volume measure and 2) that volume can increase based on the amount of air added, then here’s what you can do if your yield is over 100%.

What to do if your yield is too high?

- Check that all of your ingredients are accounted for - The number one culprit is missing water. Sometimes people take water for granted which can lead to yields that are way off. Additionally, any ingredient that you use in your cooking process, like oil, needs to be accounted for too. If not all of the oil makes its way into your end product, you would apply a waste percentage to account for just the oil that is absorbed.

- Don’t Round Up - If your recipe makes 4.5 packages, don’t round up to 5. The package amount does not need to be a whole number and rounding up will throw off your yield calculation.

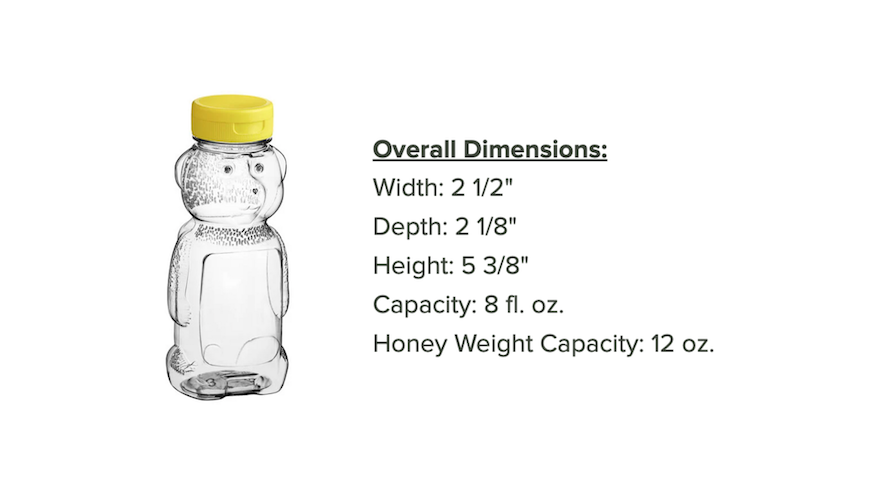

- Put it in the packaging - This goes back to the distinction of volume vs weight. Sometimes people wrongly assume that the volume of their packaging container is its weight. Just because you're using an 8 oz bottle doesn't mean the weight of your contents is 8 oz. You can easily sort this out by weighing one package (minus the weight of the package itself).

As an example of the weight vs. volume issue, let’s say someone is making a spice blend that they package in a 4 oz jar. The jar size actually refers to the volume. In order to figure out the net weight per package, you can weigh the contents that go into a bottle, since different blends can have different weights even if they’re in the same container.

Below is an example of Trader Joe’s spices which all use the same size bottle, but each have a different weight.

Here’s another example with honey. The iconic bear honey bottle is 8 fluid ounces, however the weight of the honey it can hold is 12 ounces.

Wrapping It Up

The yield is straightforward, but it’s possible to get thrown off by typos in quantities, missing ingredients, or inaccurate units. Pay special attention to your net weight per package and make sure you’re not inadvertently using a volume measure as a weight measure. ReciPal does its best to clue you in when something seems off, but as always, you should make sure everything passes your own sense check. If something does seem off and you’re having trouble diagnosing where the problem lies, a few quick measurements can usually do the trick.